Anatomy of an LED strip

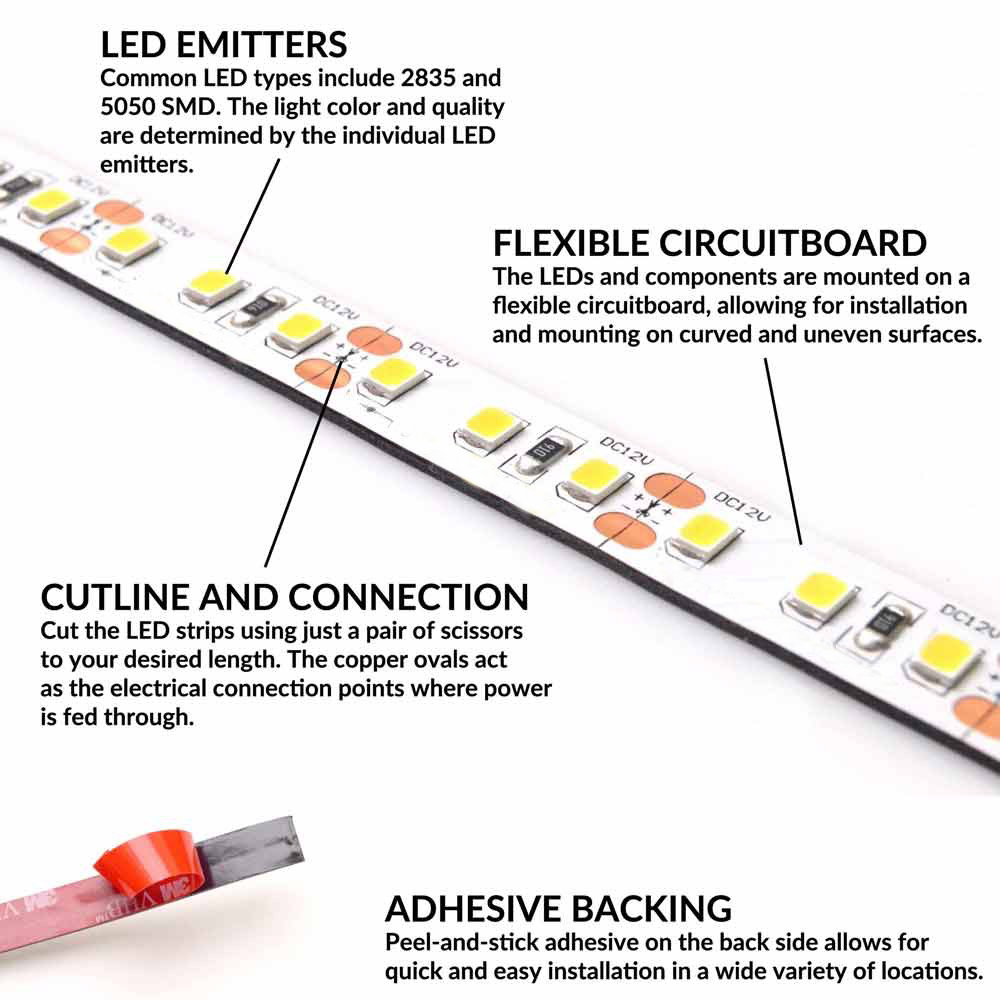

An LED strip light is typically half an inch (8-12 mm) in width, and up to 16 feet (5 meters) or more in length. They can be cut to specific lengths using just a pair of scissors along the cutlines, located every 1-2 inches.

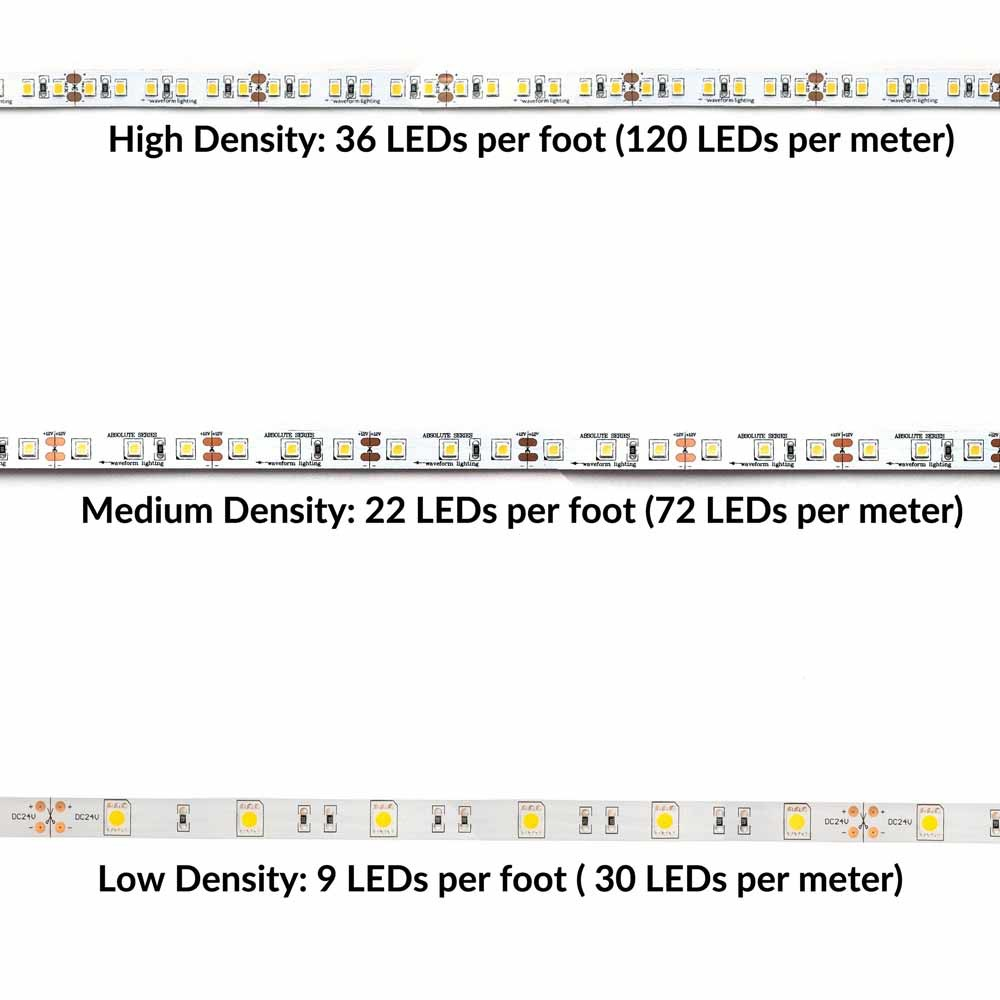

Individual LEDs are mounted along the strip, typically at densities of 18-72 LEDs per foot (60-240 per meter). The light color and quality of the individual LEDs determine the overall light color and quality of the LED strip.

The backside of the LED strip includes 3M red foam double-sided adhesive. Simply peel off the liner, and mount the LED strip to virtually any surface. Because the circuitboard is designed to be flexible, LED strips can be mounted on curved and uneven surfaces.

LED Density & Power Draw

There are various LED emitter names such as 2835, 3528, 5050 or 5730. What is most important in an LED strip is the number of LEDs per foot, and the power draw per foot.

LED density is important in determining the distance between LEDs (pitch) and whether or not there will be visible hotspots and dark spots between the LED emitters. A higher density of 36 LEDs per foot (120 LEDs per meter) will typically provide the best, most evenly distributed lighting effect. LED emitters are the most expensive component of LED strip manufacturing, so be sure to account for LED density differences when comparing LED strip prices.

Next, consider an LED strip light’s power draw per foot. The power draw tells us the amount of power the system will consume, so this is important to determine your electricity costs and power supply requirements (see below). A good quality LED strip should be capable of providing 4 watts per foot or more (15 W/meter).

Finally, do a quick check to determine if the individual LEDs are being overdriven by dividing the wattage per foot by the LED density per foot. For an LED strip product, it is usually a good sign if the LEDs are not driven at more than 0.2 watts each.